Visual Inspection with Visual Reporting

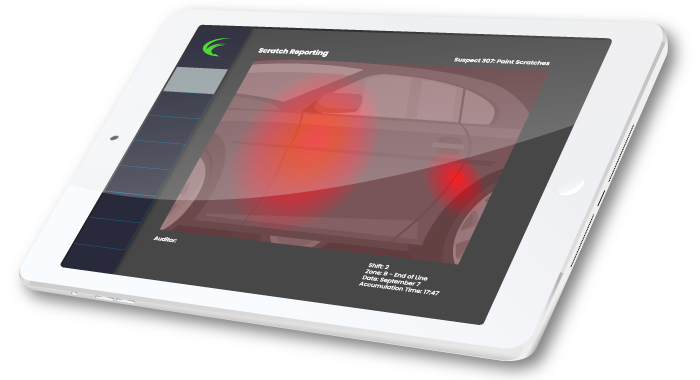

Visual inspection has been around for as long as quality for consumers has been important. It is the simplest inspection technique. Using a heat map to pinpoint ongoing quality concerns is a big step to innovating process improvement for enhanced quality practices.

The simplicity of a heat map for engineers and production managers allows them to identify and investigate defective regions, in the process eliminating other areas that they don’t need to spend time on. Failure analysis and missed issues become faster and easier to identify as the heat map establishes coloured trends.

Track non-conformance with a heat map and add image and video capture as support. EDN allows line workers/audits to record defects in real-time for management act on and reduce defect rates through corrective action.